Project Summary

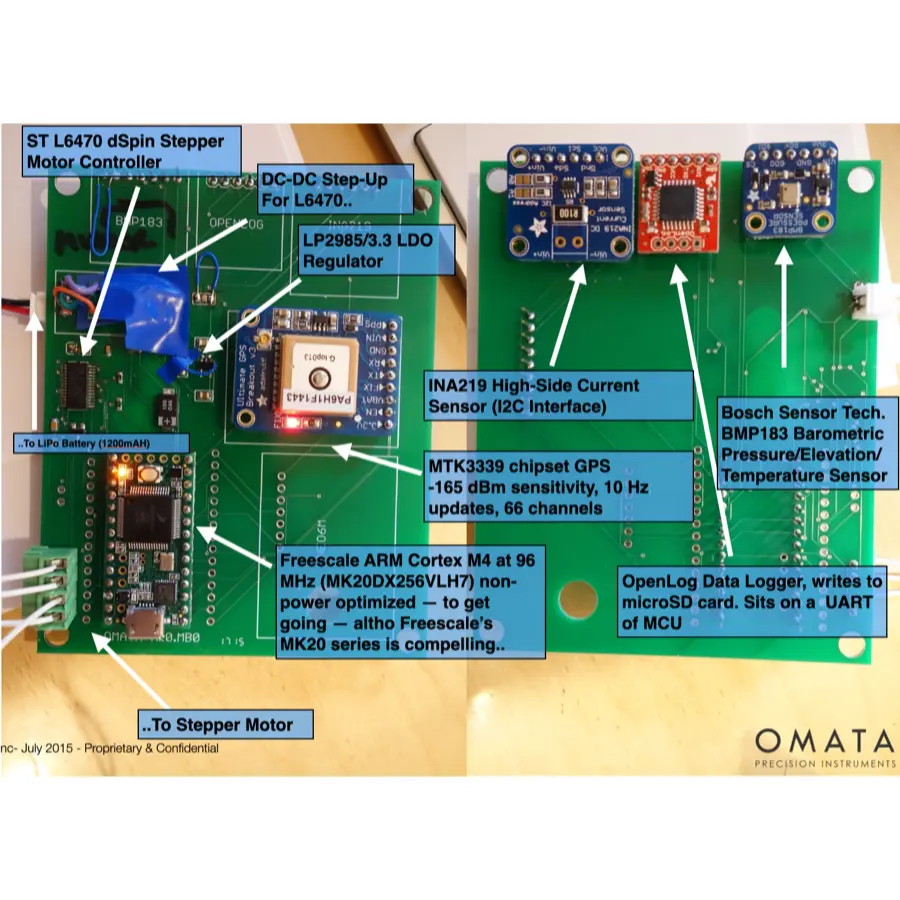

Prototyping the Omata One in this early instance was a way to work through some of the ideas in hardware. I had a fairly clear idea of the functional requirements, but needed to work through them in a grounded way rather than just drawing boxes and arrow on sheets of paper. I'd descxribe this as a macro board representing the major subsystems tha twould need to be implemented. It gave me something to point at and say, "This is what I mean by the Omata One", and could feed directly into the engineering specifications. It was a way to work through the engineering requirements and get a better sense of the overall system. (This all from the perspective of engineering dept.; of course there are the brand aspects and such, but first you need a thing that does what it says it does — later you can make sure the character of it as a brand is right and consistent. But, if the thing doesn't work, then the brand is irrelevant.)

Project Semantic Tags

ENGINEERINGHARDWAREPATENTPROTOTYPING

The Project

Early days of the Omata One project I couldn't help but to work through some of the ideas in hardware. I had a fairly clear idea of the functional requirements, but needed to work through them in a grounded way rather than just drawing boxes and arrow on sheets of paper. It's an odd sense of sense-making, knowing fairly well the overall engineering structure but then feeling incomplete for not having built something.

THis is effectively the first macro board of the Omata One. It captured GPS data, translated GPS-measured speed to displacement of a (relatively enormous, but the smallest I could find that had a small minimum step angle) stepper motor that had a little blue flag attached to it.

It also recorded location data, because I wanted to rn through to get a better sense of GPS accuracy, and get familiar with the idioms of GPS modules, and so forth.

If I had not done this, I would have been relying too heavily and not in a great position to set the engineering vision and requirements for the DFM R&D team at Haltian. They're great engineers, but there are definitely some things they would have done that I would have preferred not to have done, or done differently. (There was one aspect of the engineering design where this happened but I do not recall precisely what it was, but when that came up, I was certainly relieved that I had done this early prototyping work.)

Working at this level, close to the metal, also gave me the insight into the unique mechanical and electrical aspects of the product, which was then vital to articulating its uniqueness for a patent filing, which was successfully granted by the USPTO. I effectively wrote that patent myself, with a light review from my legal team. Part of the reason for doing it independently was the practical aspect of the business which was that it was effectively just me working on such things, and there was no budget for a lawyer to do the entirety of the patent writing.

I think this is a superlative example of the kind of work that I do, and how it can be useful to have a prototype that is not just a sketch, but something that can be used to work through the engineering requirements and get a better sense of the overall system. (This all from the perspective of engineering dept.; of course there are the brand aspects and such, but first you need a thing that does what it says it does — later you can make sure the character of it as a brand is right and consistent. But, if the thing doesn't work, then the brand is irrelevant.)

The Outcomes

Having the skillset and temperment and drive to do this kind of work is a huge advantage here. Same would go for having at least the temperement and motivation to develop the OMATA iOS App, which I also developed rather than farming the work out to a third party where you basically get an expensive App, and no understanding of how it works or ability to change it without more expense.

See Also

Use the Contact Form below to discuss how you can engage Near Future Laboratory to help you make sense of your organization's possible futures.